LPBF Manufacturing

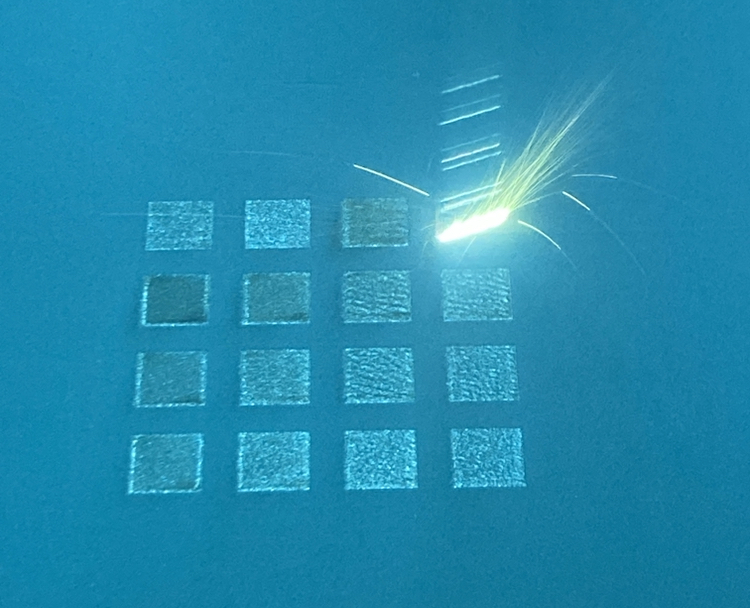

Part Production: Laser Fusion Solutions is foremost a production center using LPBF technology. This basis allows us to understand the real-life concerns and needs of the manufacturing community. We have numerous in house for this work which includes EOS M280’s, an EOS M270, and a Concept Laser XLine 1000R.

Reverse Engineering/DfAM: Occasionally, parts need to be reverse engineered or modified for printability in a LPBF environment. This could be as simple as adding a fillet or as complex as making an organic shape. From material matching/compatibility research to combining an assembly of parts into a single file, Laser Fusion Solutions can help you solve your problem and end up with a successful part.

Laser Fusion Solutions newest addition is the Concept Laser X1000R. The printer is already undergoing repairs and will hopefully be performing jobs in the next few months.

Research and Development

The team at Laser Fusion Solutions has extensive knowledge in machine and sensor design and implementation. This allows for the confidence to attack difficult materials and novel issues head on. The team has worked on and has successfully printed novel materials. Some of these materials may require a machine modification or update, with the team’s history of refurbishing equipment we have the confidence of succesfully completely this task.

Sensors are not always straight forward in the ability to mount to LPBF machines based on existing layouts. The team has modified existing machines to allow for the additional sensors often needed by research institutes without negatively impacting the build capabilities of the machine. We offer this as a unique service to the industry.